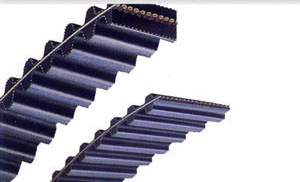

Rubber double-sided toothed synchronous belt

Rubber double-sided toothed synchronous belt

DH rubber double-sided tooth synchronous belt

Cixi XINLAN Synchronous Belt Co., Ltd.

Production materials: Rubber, glass fiber thread, nylon high stretch cloth

Processing Equipment: Steam cylinder mould, mould pressing

Delivery cycle: 1~5 days

Application areas: Machinery, textiles, precision instruments, petrochemicals, communication cables, etc.

Brief introduction of DH rubber double-sided tooth synchronous belt

1. The pitch and tooth profile parameters of DH rubber double-sided tooth synchronization are equivalent to those of H rubber single-sided tooth synchronous belts.

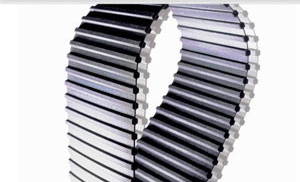

2. DH rubber double-sided tooth synchronization can be divided into two standard types according to the distribution of the tooth shape: the tooth shape is arranged in a symmetrical manner is the DA type DH rubber double-sided tooth synchronization (figure DA), and the tooth shape is arranged in a crossed manner It is a DB type DH rubber double-sided tooth synchronization (Figure DB).

The belt body layer of the DH rubber double-sided toothed synchronous belt is made of high-quality neoprene imported from Japan, the skeleton layer is made of high-quality glass fiber cord imported from Japan, and the tooth surface wear-resistant layer is protected by nylon 66 high elastic cloth. DH rubber double-sided tooth timing belt has the characteristics of good dynamic flexing, good anti-cracking performance, excellent ozone performance, aging resistance, heat resistance, oil resistance, abrasion resistance and so on.

Precautions for storage, installation and use of DH rubber double-sided tooth synchronous belt

1. It is strictly forbidden to excessively break or bend the DH rubber double-sided toothed synchronous belt to avoid damage to the strong layer and lose its use value.

2. Do not store the DH rubber double-sided toothed synchronous belt in an abnormally bent state for a long time.

3. Keep the DH rubber double-sided tooth timing belt in a cool place.

4. When installing, please shorten the center distance, loosen the tension pulley, and do not force the belt from the lower flange of the pulley to drag and grind into it.

5. The teeth of the DH rubber double-sided toothed synchronous belt must be at right angles to the running direction of the synchronous belt wheel.

6. The parallelism of the main shaft of the driving wheel and the driven wheel is controlled at about tangent = 1/1000.Inaccurate shaft position directly affects the service life.

7. It is found that the DH rubber double-sided toothed synchronous belt on the driving wheel is offset to one side, and the driven wheel should be moved to adjust, and the pressure of the tensioning wheel should be adjusted.

8. When starting, the center distance changes, the DH rubber double-sided toothed synchronous belt is loose, and the phenomenon of tooth skipping occurs. Check whether the pulley frame is loose and whether the shaft positioning is inaccurate.To be adjusted and reinforced.

9. DH rubber double-sided toothed synchronous belts must be properly tensioned according to different models and bandwidths when installing.

10. The tensioning wheel must be installed on the loose side of the driven transmission.

The characteristics of DH rubber double-sided tooth synchronous belt transmission

DH rubber double-sided toothed synchronous belt is mainly used for double-sided transmission, with the characteristics of synchronization, simultaneous and double efficiency.It shows its excellence when it requires a belt to drive and the direction is opposite, the installation location is particularly compact, or in other fields with high transmission requirements such as the main drive and auxiliary drive linkage; the DH rubber double-sided toothed synchronous belt has a light structure , Non-slip meshing transmission, low noise and other characteristics are recognized, recognized and widely used by the majority of machinery, textiles, precision instruments, petrochemicals, communication cables and other industries.

| model | Nodal line length (mm) | Number of teeth | model | Nodal line length (mm) | Number of teeth | model | Nodal line length (mm) | Number of teeth |

| 200D-H | 508.00 | 40 | 515D-H | 1308.10 | 103 | 1000D-H | 2540.00 | 200 |

| 205D-H | 520.70 | 41 | 520D-H | 1320.80 | 104 | 1020D-H | 2590.80 | 204 |

| 210D-H | 533.40 | 42 | 525D-H | 1333.50 | 105 | 1050D-H | 2667.00 | 210 |

| 220D-H | 558.80 | 44 | 530D-H | 1346.20 | 106 | 1085D-H | 2755.90 | 217 |

| 225D-H | 571.50 | 45 | 540D-H | 1371.60 | 108 | 1100D-H | 2794.00 | 220 |

| 230D-H | 584.20 | 46 | 550D-H | 1397.00 | 110 | 1120D-H | 2844.80 | 224 |

| 240D-H | 609.60 | 48 | 555D-H | 1409.70 | 111 | 1130D-H | 2870.20 | 226 |

| 245D-H | 622.30 | 49 | 560D-H | 1422.40 | 112 | 1140D-H | 2895.60 | 228 |

| 250D-H | 635.00 | 50 | 565D-H | 1435.10 | 113 | 1150D-H | 2921.00 | 230 |

| 255D-H | 647.70 | 51 | 570D-H | 1447.80 | 114 | 1170D-H | 2971.80 | 234 |

| 260D-H | 660.40 | 52 | 580D-H | 1473.20 | 116 | 1175D-H | 2984.50 | 235 |

| 270D-H | 685.80 | 54 | 585D-H | 1485.90 | 117 | 1200D-H | 3048.00 | 240 |

| 280D-H | 711.20 | 56 | 590D-H | 1498.60 | 118 | 1250D-H | 3175.00 | 250 |

| 285D-H | 723.90 | 57 | 600D-H | 1524.00 | 120 | 1260D-H | 3200.40 | 252 |

| 290D-H | 736.60 | 58 | 605D-H | 1536.70 | 121 | 1270D-H | 3225.80 | 254 |

| 300D-H | 762.00 | 60 | 610D-H | 1549.40 | 122 | 1325D-H | 3365.50 | 265 |

| 310D-H | 787.40 | 62 | 625D-H | 1587.50 | 125 | 1350D-H | 3429.00 | 270 |

| 315D-H | 800.10 | 63 | 630D-H | 1600.20 | 126 | 1360D-H | 3454.40 | 272 |

| 320D-H | 812.80 | 64 | 640D-H | 1625.60 | 128 | 1380D-H | 3505.20 | 276 |

| 325D-H | 825.50 | 65 | 650D-H | 1651.00 | 130 | 1400D-H | 3556.00 | 280 |

| 330D-H | 838.20 | 66 | 660D-H | 1676.40 | 132 | 1440D-H | 3657.60 | 288 |

| 335D-H | 850.90 | 67 | 670D-H | 1701.80 | 134 | 1450D-H | 3683.00 | 290 |

| 340D-H | 863.60 | 68 | 680D-H | 1727.20 | 136 | 1460D-H | 3708.40 | 292 |

| 345D-H | 876.30 | 69 | 690D-H | 1752.60 | 138 | 1500D-H | 3810.00 | 300 |

| 350D-H | 889.00 | 70 | 695D-H | 1765.30 | 139 | 1510D-H | 3835.40 | 302 |

| 355D-H | 901.70 | 71 | 700D-H | 1778.00 | 140 | 1535D-H | 3898.90 | 307 |

| 360D-H | 914.40 | 72 | 710D-H | 1803.40 | 142 | 1550D-H | 3937.00 | 310 |

| 365D-H | 927.10 | 73 | 720D-H | 1828.80 | 144 | 1560D-H | 3962.40 | 312 |

| 370D-H | 939.80 | 74 | 725D-H | 1841.50 | 145 | 1600D-H | 4064.00 | 320 |

| 375D-H | 952.50 | 75 | 730D-H | 1854.20 | 146 | 1630D-H | 4140.20 | 326 |

| 380D-H | 965.20 | 76 | 740D-H | 1879.60 | 148 | 1660D-H | 4216.40 | 332 |

| 390D-H | 990.60 | 78 | 750D-H | 1905.00 | 150 | 1680D-H | 4267.20 | 336 |

| 395D-H | 1003.30 | 79 | 770D-H | 1955.80 | 154 | 1700D-H | 4318.00 | 340 |

| 400D-H | 1016.00 | 80 | 775D-H | 1968.50 | 155 | 1765D-H | 4483.10 | 353 |

| 405D-H | 1028.70 | 81 | 785D-H | 1993.90 | 157 | 1855D-H | 4711.70 | 371 |

| 410D-H | 1041.40 | 82 | 800D-H | 2032.00 | 160 | 2010D-H | 5105.40 | 402 |

| 420D-H | 1066.80 | 84 | 810D-H | 2057.40 | 162 | 2100D-H | 5334.00 | 420 |

| 425D-H | 1079.50 | 85 | 820D-H | 2082.80 | 164 | 2200D-H | 5588.00 | 440 |

| 430D-H | 1092.20 | 86 | 830D-H | 2108.20 | 166 | 2360D-H | 5994.40 | 472 |

| 445D-H | 1130.30 | 89 | 840D-H | 2133.60 | 168 | 2500D-H | 6350.00 | 500 |

| 450D-H | 1143.00 | 90 | 850D-H | 2159.00 | 170 | 2680D-H | 6807.20 | 536 |

| 455D-H | 1155.70 | 91 | 860D-H | 2184.40 | 172 | 2700D-H | 6858.00 | 540 |

| 460D-H | 1168.40 | 92 | 880D-H | 2235.20 | 176 | |||

| 465D-H | 1181.10 | 93 | 895D-H | 2273.30 | 179 | |||

| 470D-H | 1193.80 | 94 | 900D-H | 2286.00 | 180 | |||

| 480D-H | 1219.20 | 96 | 930D-H | 2362.20 | 186 | |||

| 485D-H | 1231.90 | 97 | 950D-H | 2413.00 | 190 | |||

| 490D-H | 1244.60 | 98 | 960D-H | 2438.40 | 192 | |||

| 500D-H | 1270.00 | 100 | 980D-H | 2489.20 | 196 | |||

| 510D-H | 1295.40 | 102 | 985D-H | 2501.90 | 197 |