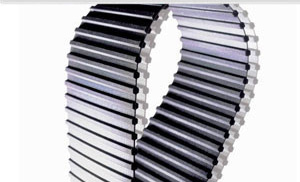

Rubber opening belt

Rubber opening belt

T2.5 rubber opening synchronous belt

Cixi XINLAN Synchronous Belt Co., Ltd.

Production materials: High-quality rubber raw materials, high-strength glass fiber cord, high-strength tooth surface cloth

Processing Equipment: Steam cylinder mould

Delivery cycle: 1~3 days

Application areas: Door machine system (automatic door, automatic curtain machine) and other properties are suitable for linear reciprocating motion

The belt body of the T2.5 rubber opening synchronous belt adopts imported high-quality synthetic neoprene and is equipped with a variety of rubber accessories for different purposes; the skeleton material is imported high-quality glass fiber cord; the toothed surface is protected by nylon 66 high elastic cloth .

The transmission performance of the T2.5 rubber open synchronous belt is similar to that of the T2.5 rubber synchronous belt. It can be widely used in textile, light industry, chemical industry, machine tool and other general machinery to transmit power, and is suitable for multi-axis transmission.Customers can flexibly cut according to actual needs.

The model and specifications of T2.5 rubber open synchronous belt are the same as T2.5 rubber single-tooth synchronous belt, which is made by spiral cutting with a large-size mold.

Application range of T2.5 rubber opening synchronous belt

The door machine system (automatic door, automatic curtain machine) and other performances are suitable for linear reciprocating motion, with accurate positioning and large carrying capacity, which is the best choice for reciprocating positioning transmission

T2.5 rubber opening synchronous belt material

High-quality rubber raw materials, high-strength glass fiber cord, high-strength tooth surface cloth

Precautions when using T2.5 rubber open synchronous belt:

1. When purchasing, pay attention to the clean surface of the T2.5 rubber opening timing belt, the belt is not twisted and deformed, and the belt teeth are full.

2. T2.5 rubber opening timing belt products must not be twisted, so as not to damage the frame material and affect the strength of the belt.

3. It is strictly forbidden to scratch the T2.5 rubber opening timing belt to avoid early damage to the belt. Avoid contact with chemicals (especially strong oxidizing acids, such as concentrated sulfuric acid, etc.) for T2.5 rubber opening timing belts.

4. Try to avoid long-term contact with oil and water for T2.5 rubber opening timing belt.

5. When replacing the T2.5 rubber opening timing belt, the tension of the belt must be minimized before it can be taken out. It is strictly forbidden to use non-professional tools to pry down the T2.5 rubber opening timing belt under the condition of high tension.

T2.5 rubber opening synchronous belt connection method:

Generally adopt the method of T2.5 synchronous belt tooth plate to fix and connect.

| specification | Knot line length | Number of teeth |

| T2.5×145 | 145.00 | 58 |

| T2.5×160 | 160.00 | 64 |

| T2.5×172.5 | 172.50 | 69 |

| T2.5×200 | 200.00 | 80 |

| T2.5×230 | 230.00 | 92 |

| T2.5×245 | 245.00 | 98 |

| T2.5×265 | 265.00 | 106 |

| T2.5×272.5 | 272.50 | 109 |

| T2.5×275 | 275.00 | 110 |

| T2.5×285 | 285.00 | 114 |

| T2.5×300 | 300.00 | 120 |

| T2.5×305 | 305.00 | 122 |

| T2.5×330 | 330.00 | 132 |

| T2.5×335 | 335.00 | 134 |

| T2.5×355 | 355.00 | 142 |

| T2.5×380 | 380.00 | 152 |

| T2.5×420 | 420.00 | 168 |

| T2.5×480 | 480.00 | 192 |

| T2.5×500 | 500.00 | 200 |

| T2.5×512.5 | 512.50 | 205 |

| T2.5×580 | 580.00 | 232 |

| T2.5×620 | 620.00 | 248 |

| T2.5×625 | 625.00 | 250 |

| T2.5×690 | 690.00 | 276 |

| T2.5×780 | 780.00 | 312 |