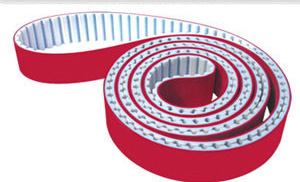

Polyurethane single tooth synchronous belt

Polyurethane single tooth synchronous belt

S5M polyurethane single tooth synchronous belt

Cixi XINLAN Synchronous Belt Co., Ltd.

Production materials: Polyurethane (PU), steel wire rope, Kevlar wire

Processing Equipment: 模压

Delivery cycle: 1~5 days

Application areas: Food, tobacco, feed, ceramics, glass, household appliances, cargo handling, printing, textile printing and dyeing, construction materials, heavy industry, etc.

S5M polyurethane timing belt is made of thermoplastic polyurethane material, which has high abrasion resistance. Various types of steel wire cores ensure that it is transmitted

It still maintains good athletic ability during movement, with small production tolerances.In the production process, a layer of nylon is added to the tooth surface and the back of the tooth to ensure that the operation characteristics in special applications remain unchanged, and a layer of polyurethane can be thickened on the back of the belt to prevent corrosion or high load.

The structure of S5M polyurethane timing belt is composed of belt back, tensile layer and belt teeth.

(1) S5M polyurethane timing belt with back

The back of the S5M polyurethane timing belt is used to bond and wrap the tensile elements. It should have good flexibility and flex fatigue resistance, not easy to age, good oil resistance, and abrasion resistance. It is on the inner surface of the back of the S5M polyurethane timing belt. A sharp-angled groove of appropriate size can not only improve the flexural fatigue performance of the toothed belt due to process requirements, but also allow the intercepted air between the belt and the gear teeth to escape during operation to eliminate part of the noise.

(2) Wire rope (or Kevlar wire) tensile layer

The tensile layer is the tensile element of the timing belt, which is used to transmit power and ensure that the pitch of the timing belt remains unchanged when it is working.It uses a multi-strand steel wire rope (or polyester cord) to spirally wind the cloth along the width of the tape, and its position is set as the pitch line of the timing belt.The tensile layer must have high tensile strength and bending fatigue strength.The elastic modulus is large, and no elongation is allowed during work, so as to ensure that the pitch of the timing belt remains unchanged.

(3) Polyurethane timing belt with teeth

The teeth of S5M polyurethane timing belt should have high shear strength, good wear resistance and oil resistance.The pitch distribution of the belt teeth is required to be very high, and the belt teeth should be correctly meshed with the tooth grooves of the belt wheel. Therefore, the correctness of the geometric parameters of the belt teeth needs to be strictly required. S5M polyurethane timing belt is known for its excellent oil resistance and abrasion resistance. It is suitable for high-speed operation of medium and small power. The environment should be relatively dry. The working temperature is generally -20~+80 C.

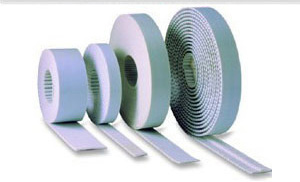

The S5M polyurethane endless power belt is produced through a special molding process.The high-quality polyurethane material makes the belt wear-resistant and tear-resistant.The steel wire core increases the belt strength and tensile strength, so that the belt has good dimensional stability.

S5M polyurethane ring-type power belt has a small tolerance, which can ensure the accuracy of thickness and length.The above various characteristics make S5M polyurethane ring-type power belt have high physical and chemical stability. S5M polyurethane seamless timing belt is suitable for high-strength, high-precision and even high-speed transmission systems, and is most suitable for low-load synchronous and grading transmission, such as office automation systems and household appliances.

S5M polyurethane timing belt has the following properties:

Mechanical properties: stable dimensions, low pre-tension, low noise, high wear resistance, no maintenance, good flexibility, linear speed up to 80 m/s

Chemical performance: anti-aging, water-repellent, anti-ultraviolet UVA, anti-ozone, highly oil-proof, oil-proof ester, anti-corrosion of most acids and alkalis

Working temperature: -30℃~+80℃, can withstand up to +110℃ in a short time

| specification | Knot line length | Number of teeth | specification | Knot line length | Number of teeth |

| STS5M-150 | 150.00 | 30 | STS5M-625 | 625.00 | 125 |

| STS5M-250 | 250.00 | 50 | STS5M-650 | 650.00 | 130 |

| STS5M-255 | 255.00 | 51 | STS5M-670 | 670.00 | 134 |

| STS5M-295 | 295.00 | 59 | STS5M-675 | 675.00 | 135 |

| STS5M-300 | 300.00 | 60 | STS5M-695 | 695.00 | 139 |

| STS5M-325 | 325.00 | 65 | STS5M-700 | 700.00 | 140 |

| STS5M-335 | 335.00 | 67 | STS5M-710 | 710.00 | 142 |

| STS5M-340 | 340.00 | 68 | STS5M-750 | 750.00 | 150 |

| STS5M-355 | 355.00 | 71 | STS5M-800 | 800.00 | 160 |

| STS5M-375 | 375.00 | 75 | STS5M-810 | 810.00 | 162 |

| STS5M-400 | 400.00 | 80 | STS5M-850 | 850.00 | 170 |

| STS5M-410 | 410.00 | 82 | STS5M-900 | 900.00 | 180 |

| STS5M-420 | 420.00 | 84 | STS5M-950 | 950.00 | 190 |

| STS5M-425 | 425.00 | 85 | STS5M-975 | 975.00 | 195 |

| STS5M-475 | 475.00 | 95 | STS5M-1000 | 1000.00 | 200 |

| STS5M-490 | 490.00 | 98 | STS5M-1050 | 1050.00 | 210 |

| STS5M-500 | 500.00 | 100 | STS5M-1125 | 1125.00 | 225 |

| STS5M-520 | 520.00 | 104 | STS5M-1270 | 1270.00 | 254 |

| STS5M-525 | 525.00 | 105 | STS5M-1350 | 1350.00 | 270 |

| STS5M-550 | 550.00 | 110 | STS5M-1420 | 1420.00 | 284 |

| STS5M-560 | 560.00 | 112 | STS5M-1595 | 1595.00 | 319 |

| STS5M-575 | 575.00 | 115 | STS5M-1800 | 1800.00 | 360 |

| STS5M-600 | 600.00 | 120 | STS5M-2000 | 2000.00 | 400 |